“TAPPING UNDER PRESSURE”

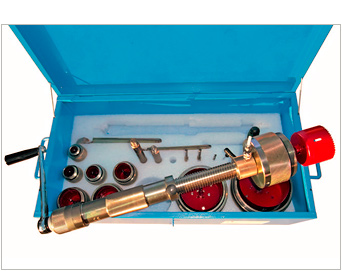

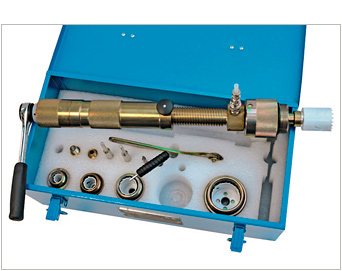

Drilling Machine description is a machine for under pressure tapping of water or gas mains. The machine is made of galvanized steel for corrosion protection. It features a simple yet sturdy design and has a wide range of use. The machine is capable of drilling holes from DN 25 to DN 150 for derivations from gas and water pipes with working pressure up to 12 bars. The machine will make a quality tap in every type of material provided the appropriate drilling core bit is selected. The advantage of the machine is its capability to control and maintain a steady pressure of the drill onto the pipe. This can be done thanks to the special pressing clutch spring which ensures fast drilling with low effort. The drilled material does not crumble and it is totally recovered after the tapping is completed since the pressure onto the pipe is evenly distributed. The machine can perform tapping in every position, and it can work on threaded and flanged pipes. The machine is driven manually with a ratchet wrench. The tool is delivered in a steel box. Provider offers two types of machines – UNIVERSAL TYPE 22th and TYPE UNIVERSAL 20th. Both machines can be installed pneumatic or hydraulic drive, assumed a key place without any modifications.

UNIVERSAL TYPE 22

Diameter range: from 1″ to 6″

Effective feed: 220 mm

Maximum drilling depth: 600 mm

Standard version: operated manually with a ratchet wrench (crank handle).

UNIVERSAL TYPE 20

Diameter range: from 1/2 “to 2”

Effective feed: 160 mm

Maximum drilling depth: 360 mm

Standard version: operated manually with a ratchet wrench (crank handle.

The package includes:

- Body.

- Drilling core bits for steel and cast iron with diameters from 22 mm to 140 mm and with pilot.

- Body extensions

- Ratchet wrench with a crank handle.

- A set of wrenches and screwdrivers needed for proper use of the tool.

- The tool can also accept a pneumatic or hydraulic drive that can be fitted instead of the ratchet.